What Are Your Customers' Experiences Throughout Their Purchasing Journey?

The advantage of reorganizing from a product-centric to a customer-centric operation includes gaining perspective, and therefore revenue, from customer-facing units beyond the sales department.

Challenging your organization to develop beyond a withering product-centric model means looking at your business through your customers’ eyes. Our consumer lives provide countless examples for industrial automation. For instance, my mom had just finished a move to Boise which was a long time coming. It was the kind of move that represents “out with the old and in with the new,” so an old recliner was left behind with an expectation for a new one. The store that was chosen had done their marketing well enough to get us into their showroom to upgrade my mom’s living room entertainment and relaxation. The salesperson, however, made no inquiries and was only okay at informing us about available options on each of the recliners. His tactics were lacking. He didn’t question what brought us to that particular store on that specific day and didn’t get near inquiring about what led my mom to choose a recliner that day or how she would use it.

There’s a reason for using a recliner purchase as an industrial sales example. Imagine the ignoble profession of a recliner salesperson. I don’t mean to disparage recliner salespeople, but I imagine that most sales engineers in industrial automation picture their profession garnering more public respect than selling recliners. My point is not to pick on recliner salespeople nor is it to make them feel better than shoe salespeople but to have us agree on the premise that an industrial automation sales channel should be objectively more strategic than recliner sales. Industrial automation companies instinctively rely on strategy to win complex sales. Those tendencies can be used for the required evolution to become a customer-centric organization.

The purpose of this post is to persuade industrial automation suppliers to include their customers’ maintenance operations in their strategic planning to be a customer-centric organization. Restructuring for a customer-centric approach begins and ends with your customers’ viewpoints. Knowing your customers’ experiences with your product in their maintenance operations offers insight into your customers’ challenges, which is essential for a successful customer-centric organization.

Strategy and Tactics for Complex Sales

A customer-centric plan aims at strategic selling for complex sales and customer retention at an organizational level. Industrial automation salespeople have trained for decades to win complex sales.

Sales are the lifeblood of any business. In The New Strategic Selling by Heiman and Miller (1998), a good sales strategy is described as one that gets yourself “in the right place with the right people at the right time so that you can make the right tactical presentation.” In their book, they differentiate between the traditional stereotype of glad-handing salespeople and strategizing for the benefit of all who are involved in a customer account.

Heimen and Miller train salespeople how to address the “Six Key Elements” for strategic sales success:

- Buying Influences

- Red Flags/Leverage from Strength

- Response Modes

- Win-Results

- Ideal Customer Profile

- Sales Funnel

The days of simply relying on face-to-face selling have evolved from individual strategizing. Industrial automation suppliers and machine builders need to align their companies with their customers’ interests. The alignment is driven by their customers’ perspectives and goals if the supplier wants to flourish. Advice about business development techniques that can be used to effectively recruit and respond to manufacturing customers is in my March 2020 post: Lead Response Management. The post is about how to approach customers through their buying practices rather than your sales issues. Evolving beyond product-centric approaches to create an organizational customer-centric strategy leans on some existing sales tactics.

Maintaining Customer Relationships

A customer-centric organization focuses on proving to customers that they are valuable at every stage of their purchasing journey, which has been the practice of individual professional sales engineers.

"The time to repair the roof is when the sun is shining,” John F. Kennedy

The sale is only the beginning. Professional sales engineers establish a plan to maintain customer relationships if they want continuous sales. A sample plan is provided in the appendix of Mastering Technical Sales: The Sales Engineer’s Handbook.

“The key is to have a strategy that will at least let you keep in touch with your key contacts while consuming appropriate amounts of your time. Post-sales activity can seem like a lot of work, but many benefits actually accrue to the salesperson and their company.

“Personal References: Handling a customer correctly after the sale means they can act as a reference for you in future sales engagements. Customers that are willing to accept calls from future prospects will justify your time spent during post-sales activities by saving you time with less busywork needed to convince future prospects.

“Maintain Relationships for Add-on Sales: A long-term benefit of being engaged with the customer is the relationships that are built. Remember that sharing information should benefit the customer more than you. Benefits, not features, sell. Benefits clearly answer the customer questions ‘What’s in it for me?’ or ‘What results will I get that will improve my current situation?’ or ‘Will it make me healthier, wealthier or wiser?’ The most compelling benefits are those that provide an emotional or financial return."

An example of expanding an individual’s post-sales activities to an organizational strategy is the installation and maintenance of the product. Both provide excellent insight into the customer’s experience with your product and are outstanding opportunities to enhance a longterm relationship at the account level. Small companies are able to communicate with one another to coordinate pre- and post-sales activities to benefit the customer, but strategically planned solutions units are required when companies expand beyond a few key job functions.

Customer-centric Viewpoint

Maintenance services are ripe for industrial automation companies to deliver experiences linked to key customer value propositions that lead to their customers' improved profit performance.

Have you purchased your own product recently? For my mom, purchasing the recliner was just the beginning of her experience with the recliner company and their sales channel. When it arrived, the electric recliner didn’t come with the remote which was its sole operation tool in the showroom. After getting frustrated with the incorrect and inconsiderate retailer’s salesperson, her own research on a higgledy-piggledy manufacturer’s website required her to find a buried user’s manual that specified new controls for the recliner model that had arrived. It turned out that the floor model we saw was a previous model and the new delivered model had buttons attached to the side panel under the armrest. It was uncanny to watch through my mom’s (the customer’s) eyes how related a recliner purchase was to an industrial automation sale and its fulfillment. An unprofessional salesperson and poor product support misrepresented — or probably more accurately perfectly represented! — the company that provided the product. Their focus on product and not the customer experience reduced to a slim chance any potential future business from my mom.

If you’ve accepted that thriving as a business means looking at your company through your customers’ eyes, it’s not hard to figure out what their perspective is; simply buy and use your own product. In industrial automation, installing and maintaining your product or machine can be a positive or negative experience and you should know which one it is.

Designing an Organization to be Customer-centric

Focusing on serving the maintenance operations of manufacturing customers fundamentally leads to their success by contributing to their OEE and product quality.

“Organization design is the deliberate process of configuring structures, processes, reward systems, and people practices and policies to create an effective organization capable of achieving the business strategy. The star model is a framework for thinking holistically about the five major components of organization design.

"Figure 1 depicts an organization consisting of four dimensions.

- Location of Decision-making Power.

- Information and Decision Making Processes.

- Reward System to Meet Organizational Goals.

- People Dimension Focusing on H.R. Policies.

"The message of the Star Model is that these dimensions must be consistent with strategy and consistent among themselves. The purpose here is to identify the different solutions strategies and the different combinations of organizational dimensions that characterize the more customer-centric organization that will create and deliver these solutions." J.R. Glabraith, D. Downey, A. Kates (2002). Designing Dynamic Organizations: A Hands-on Guide for Leaders at All Levels

A customer’s perspective, imperative for a compelling organizational strategy of an industrial automation supplier, is found in manufacturers’ maintenance operations. Addressing maintenance and product life-cycles is not ultimately about fixing broken parts and machines. The manufacturer’s perception of maintenance as a cost center has to be overcome with proof of how the product will produce reliable operations contributing to their bottom line. The reason machine and component suppliers struggle to overcome their sales hurdles is that they seldom address this issue. In order to provide the solution, suppliers must emerge from presenting product features to confront one of manufacturing’s main concerns. In order to address this concern, the suppliers must deliberately include it in their organizational strategy as one of their solution units. Organizing to solve an industry-specific issue like maintenance effectiveness is what Galbraith refers to as a vertical solution. Because the products supplied to maintenance departments are highly integrated with other parts of the industrial control systems, the solutions unit should reflect the same level of coordination.

Customer-centric Components

For a company to make itself known as customer-centric, customers’ experiences should be a vital part of the mission statement.

"The organization can’t be designed from the bottom up. Those on the front lines don’t have the broad perspective necessary for making the trade-offs that will affect the whole organization, whether that organization is the entire enterprise or a particular division or department. Although they can and should be involved in the design process to help identify the problems that need to be addressed and provide insight into what customers want, organization design is the responsibility of the leader and the leadership team." J.R. Glabraith, D. Downey, A. Kates (2002). Designing Dynamic Organizations: A Hands-on Guide for Leaders at All Levels

“The biggest change to an existing organization that wants to become customer-centric, is the addition of one or more solutions units. The reason that the change is a big one is that historically all the company’s units have been product-centric. This difference in orientation is a source of tension that must be overcome if the customer-centric solutions unit is to be integrated into an existing company. The contrast between the product- and customer-centric organizations is shown in Fig. 2.

“Organization design is the deliberate process of configuring structures, processes, reward systems, and people practices and policies to create an effective organization capable of achieving the business strategy. The star model is a framework for thinking holistically about the five major components of organization design."

Once the company strategy includes engaging maintenance departments, the key to becoming a customer-centric industrial automation supplier can be found. Although they have their role, the marketable value of automation isn’t in its specifications or its delivery and will never be found there. Machine builders who do not install predictive analysis to deliver components before they fail cannot possibly serve their manufacturers’ KPI requisites by making up for the lost production with supply chain logistics. Likewise, component suppliers who don’t provide actionable product lifecycle information can cause critical stock costs to rise and are probably also affecting production, among other matters. Products’ features and performance specifications alone cannot possibly overcome the destruction of manufacturers’ profits that occur during maintenance shutdowns and downtime. Organizing to meet theses needs requires first, acknowledging that it should be included in your company’s strategy, which I assume you have or would not have read this far; and it also implores the integration of maintenance solutions into the organizational fabric of industrial automation suppliers in order to become customer-centric.

Profit-centered Maintenance

A customer-centric supplier provides secure, real-time component monitoring that communicates with CMMS. Automating maintenance operations remakes a cost-center into a profit-center.

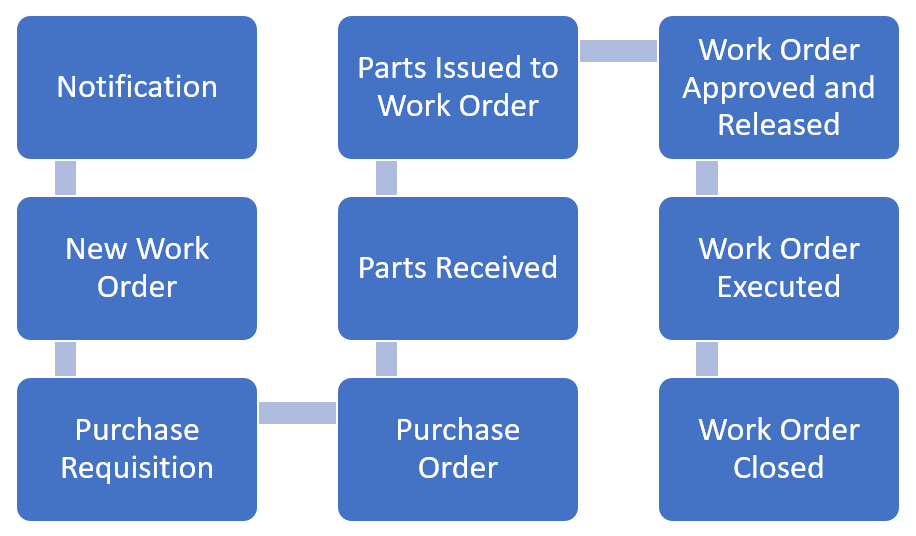

Industrial automation companies and machine builders can reorganize their departments to serve manufacturers’ maintenance issues. Sales channels would not only become more relevant to manufacturers, but each would profit simultaneously from the shared perspective. Suppliers must evolve their automation product and machine sales pitches to help manufacturers’ maintenance operations and to become customer-centric. Maintenance operations are burdened with manual processes that need fixing, and suppliers have the wherewithal to provide the solution. Automating work order processes to improve OEE and reliability is key to achieving profit-centered maintenance that contributes to manufacturers’ ambitions for Operational Excellence. Pathways7 serves maintenance departments and helps parts suppliers and machine builders do the same with reactive maintenance, planned maintenance, and predictive maintenance services:

- Reactive Maintenance: Replacing failed and obsolete parts through an informational web store

- Planned Maintenance: Actionable product Life-cycle reports

- Predictive Maintenance: Component-level temperature, vibration, and current monitoring communication with CMMS

Organizing a business to help manufacturing customers maintain the products they buy not only changes a sale from a product-centric offering to a customer-centric one, but it also offers profitable customer-facing opportunities for their suppliers.